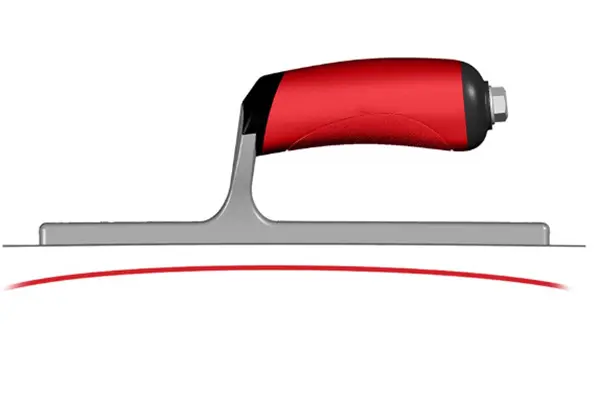

If you’ve ever observed a drywall professional in action, you might have noticed that their trusty tool, the drywall knife, possesses a distinctive curved edge. But have you ever wondered why drywall knives are curved? In this article, we’ll unravel the mystery behind this unique design feature. We’ll explore the benefits of curved drywall knives, their practicality in different scenarios, and how they contribute to achieving flawless drywall installations.

The Purpose of the Curved Edge

The curved edge of a drywall knife serves a crucial purpose in achieving smooth and seamless drywall finishes. The design feature allows the knife to have a larger contact area with the joint compound or spackle when applying and feathering it onto the drywall surface. This increased contact area enables the professional to distribute the compound evenly and efficiently, resulting in a more uniform and professional finish. The curve also helps to minimize the risk of leaving lines or marks on the surface, creating a seamless blend between the joint compound and the surrounding drywall.

The Advantages of Curved Drywall Knives

Enhanced Feathering and Tapering

One of the significant advantages of using a curved drywall knife is its ability to achieve better feathering and tapering. Feathering refers to the process of gradually thinning out the joint compound or spackle, blending it seamlessly into the surrounding drywall. The curve of the knife allows for precise control and gradual thinning of the compound, resulting in a smooth transition from the repair area to the rest of the wall or ceiling. This ensures that the repaired surface is virtually undetectable, creating a flawless finish.

Increased Efficiency and Speed

The curved edge of a drywall knife also contributes to increased efficiency and speed during the drywall finishing process. Due to its larger contact area, more compound can be applied and distributed with each stroke. This minimizes the number of passes required to achieve the desired finish, saving valuable time and effort. The efficiency of curved drywall knives allows professionals to complete projects more quickly without compromising on the quality of the finish.

Versatility in Different Drywall Applications

Curved drywall knives are versatile tools that can be used in various drywall applications. Whether it’s taping joints, applying joint compound, or feathering and smoothing surfaces, the curved edge proves its adaptability across different tasks. The design feature allows professionals to work with precision in tight corners, around edges, and on curved surfaces. The curve helps to navigate challenging areas and ensures a consistent finish throughout the project, regardless of the complexity of the drywall installation.

Conclusion

The curved edge of a drywall knife is far from a mere design quirk; it is a purposeful and indispensable feature in achieving flawless drywall finishes. The larger contact area, enhanced feathering and tapering capabilities, increased efficiency, and versatility make curved drywall knives an essential tool for professionals in the industry. By embracing the curved edge, drywall experts can effortlessly create seamless transitions, smooth surfaces, and impeccable finishes. So, the next time you witness a professional working their magic with a curved drywall knife, you’ll appreciate the secrets behind this remarkable tool.

Post time: Mar-21-2024